The Manuli Ryco Innovation Centre is the organization dedicated to the development of new products and technologies, for the benefit of the entire MR Group. Last but not least the MRIC is also the custodian of technical know how, providing training and assistance to both Manufacturing and Service Divisions.

The MRIC HQ is based in Italy, from where it coordinates four specialized centres located in China, Poland, France and the UK.

Innovation & Research activities are focused on:

Evolution of hydraulic applications is supported by co-design with OEMs, End-User, ISO/SAE/API norms organizations and university institutes. MRIC design activities are prioritized on "10 hydraulics goals" , from pressure increase to environmental sustainability.

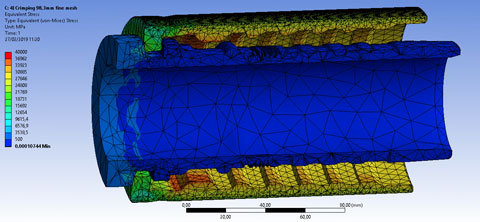

Advanced design methods such as finite element analysis, using calculation models based on 40 forty years of rubber developments. Simulation and design calculation software, supporting all engineers with fast, professional and safe product development for both OEMs and End-users.

All our compounds are designed by the MRIC team thanks to modern laboratories that allow polymers mixing and process simulation; chemical and mechanical properties are monitored by MRIC engineers from prototype to mass production. Materials are managed at central level to guarantee a uniform performance in all our global plants.

Hose assembly crimping parameters & machine development represents the "Integrated system". Hoses, fitting inserts, ferrules and crimping machines are designed to smoothly interact with each other, in order to enhance the final product's quality and performance. All projects are managed according to ISO/TR 17165-2 standards.

Hi-Tech fatigue laboratory tests, with state of the art technologies, focus on integrated system qualification. All new products are 100% tested according to both international standards and Customer specifications.

Field validations are carried out through customer co-design and on-site application engineer monitoring.

Thanks to the prototyping activities and cooperation during industrialization, MRIC supports production plants with technology process development. All new technologies are tested, analyzed and approved by MRIC in order to guarantee the final product's performance.

MRIC manages PSTS, the single point of entry for customer issues. It provides a proper technical analysis of the working conditions and applications characteristics, in order to give a satisfactory support/answer to the customer.

The Manuli Technical Academy (MTA) team is committed to maintaining and expanding the company technical knowledge about products, applications, technologies, innovation trends, quality and service. Key aims are to stimulate mutual understanding, dialogue and integration to improve operational processes for all our customers and to support internal resources development.